The transportation of solid wood furniture should be light, stable and flat. In the process of transportation, try to avoid damage, and place it stably. In case of unstable placement, pad some cardboard or thin wood pieces to make it stable.

The natural and environment-friendly solid wood furniture reveals the beauty of nature and primitive, together with its long-lasting durability and high collection value, has been popular with middle and high-end consumers. But in general, solid wood furniture will have expansion joints, because wood furniture usually has the phenomenon of thermal expansion and cold contraction. If there is no expansion space, it is easy to cause furniture cracking and deformation. And some people who don’t know how to do it think it’s furniture cracking, so what kind of sewing is cracking? What causes the solid wood furniture to crack? Is real wood furniture cracking really a quality problem? What should I do if I crack?

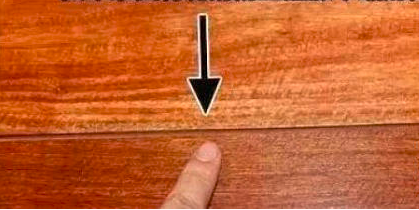

If we carefully observe some high-grade solid wood furniture, we will find that there is often a gap at the side of the furniture panel.This gap is called expansion joint or contraction joint. It is not caused by the mistakes in furniture design and production. On the contrary, expansion joints are smart “ideas” intended for them. Its existence has played an important role in controlling the physical characteristics of wood “hot expansion and cold contraction” and improving the service life of solid wood furniture.

Why do solid wood furniture have expansion joints?

Expansion joint is a kind of traditional processing technology of Chinese classical furniture. People who have some knowledge of solid wood furniture know that a pure solid wood furniture is bound to retain the fine manufacturing technology of Ming and Qing traditional furniture — mortise and mortise structure. Without using a nail, the components of furniture are assembled through the ingenious combination of mortise and mortise. Expansion joints are used to prevent the frame or tenon of furniture from cracking when the wood shrinks or expands due to the influence of the external environment, resulting in the loosening of various parts of furniture and failure of normal use.

It is necessary to treat the expansion joint on the surface of solid wood board. It is called art sewing or craft sewing. Mostly in the interface, and is two different wood grain direction!

Why does solid wood furniture crack?

1.Moisture content

The moisture content of solid wood furniture is not well controlled, and there will be quality problems such as cracking and deformation. After the production of furniture, the moisture content of wood determines whether the shape and material of furniture will change again. Therefore, it is very important to control the moisture content of solid wood furniture. The balanced moisture content will not crack and deform due to the environmental factors such as sunlight, supercooling, overheating and so on.

2.Whether

The moisture content of furniture is one to two percentage points lower than the actual average moisture content of air. Due to the difference of geographical location, the climate and weather in China are also different, so the moisture content requirements of solid wood furniture are also different. For example, the annual average moisture content of Beijing is 11.4%, so the moisture content of solid wood furniture should be controlled at 10.4% or 9.4%; the average moisture content of air in the south is 14%, and that in the north is 12% to 13%. Therefore, some solid wood furniture in the South will crack after being transported to the north.

3.Transportation

In the transportation of furniture, it is inevitable that there will be bumps and bumps. In addition, due to the climate, the transportation of solid wood furniture is even more difficult. Although solid wood furniture is stronger than other materials, it is hard to survive without good maintenance.

Post time: Oct-22-2019